Creating sustainable solutions for your plastic industry

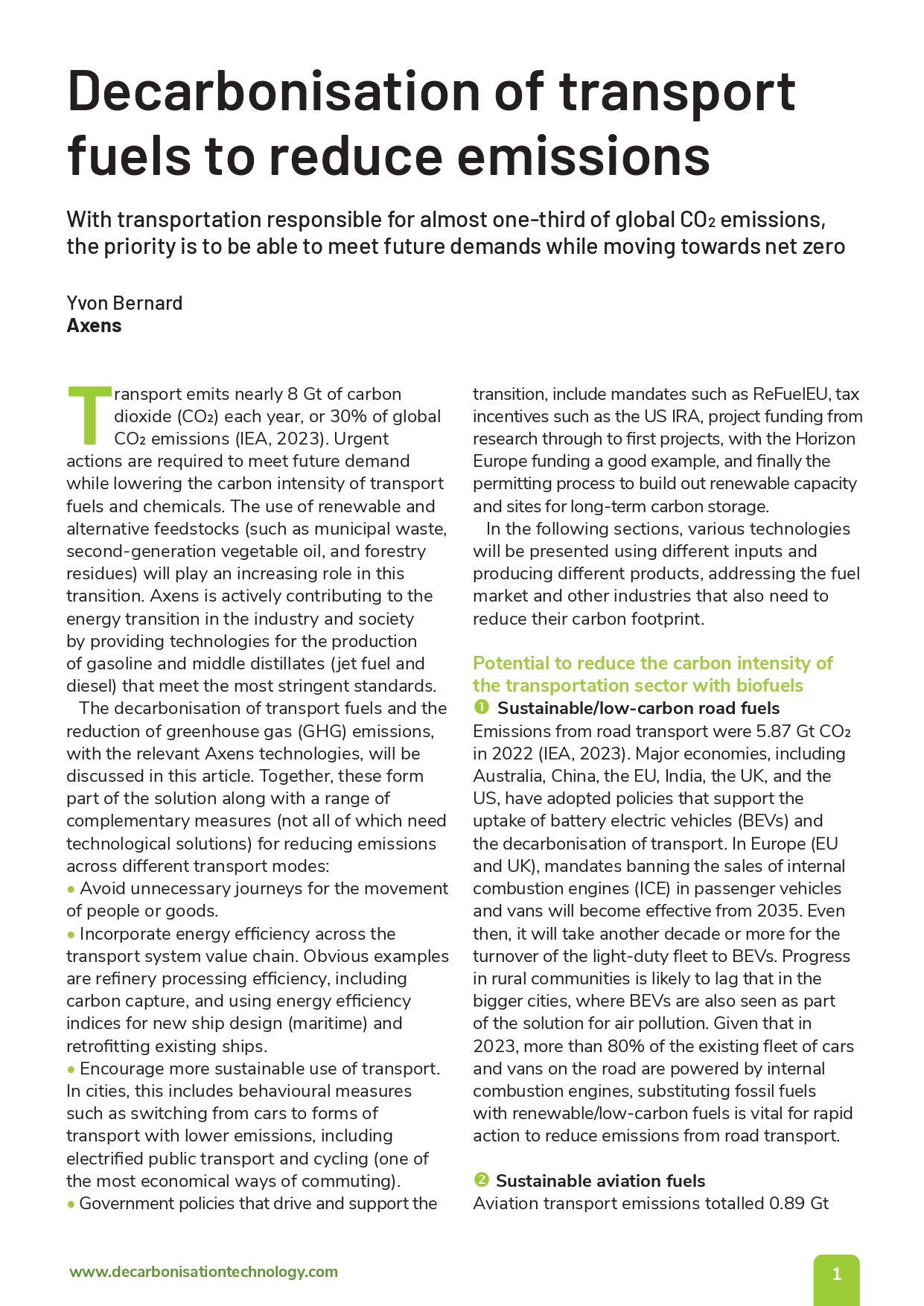

Powering the Road: the Future of EV Batteries

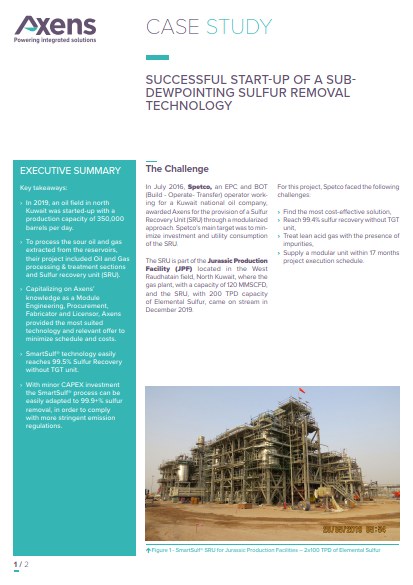

Carbon Capture and Storage

Prepare for Takeoff

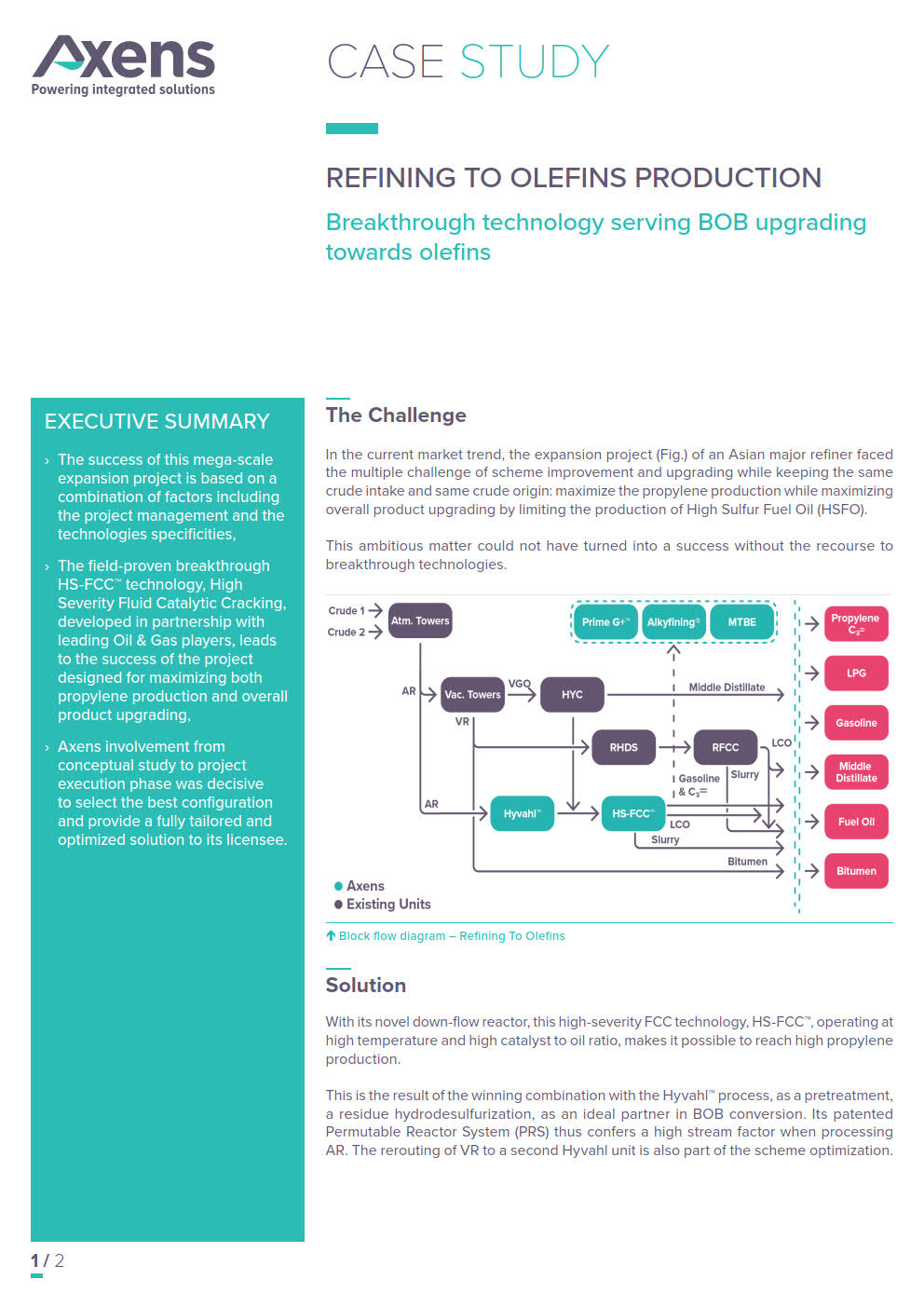

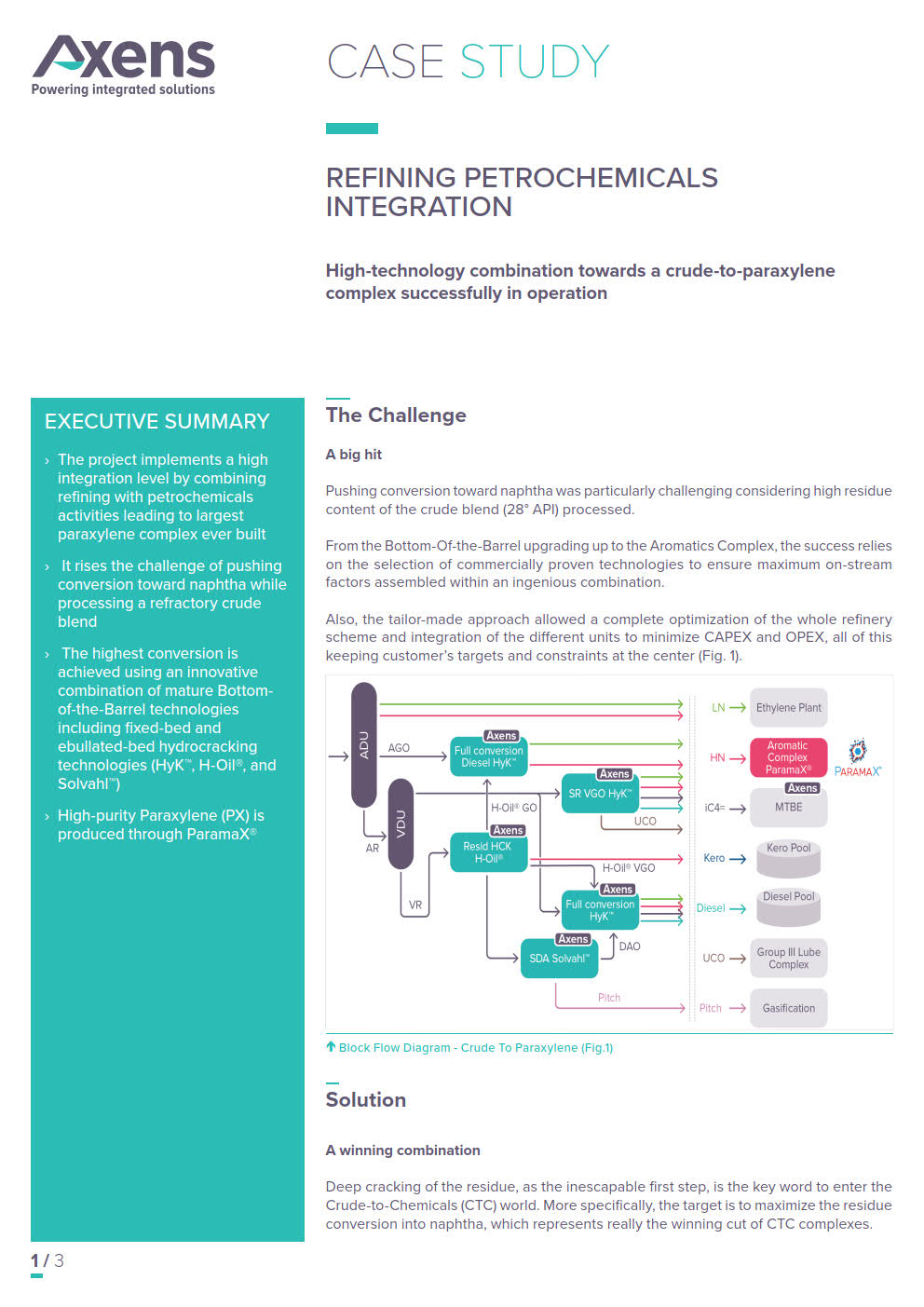

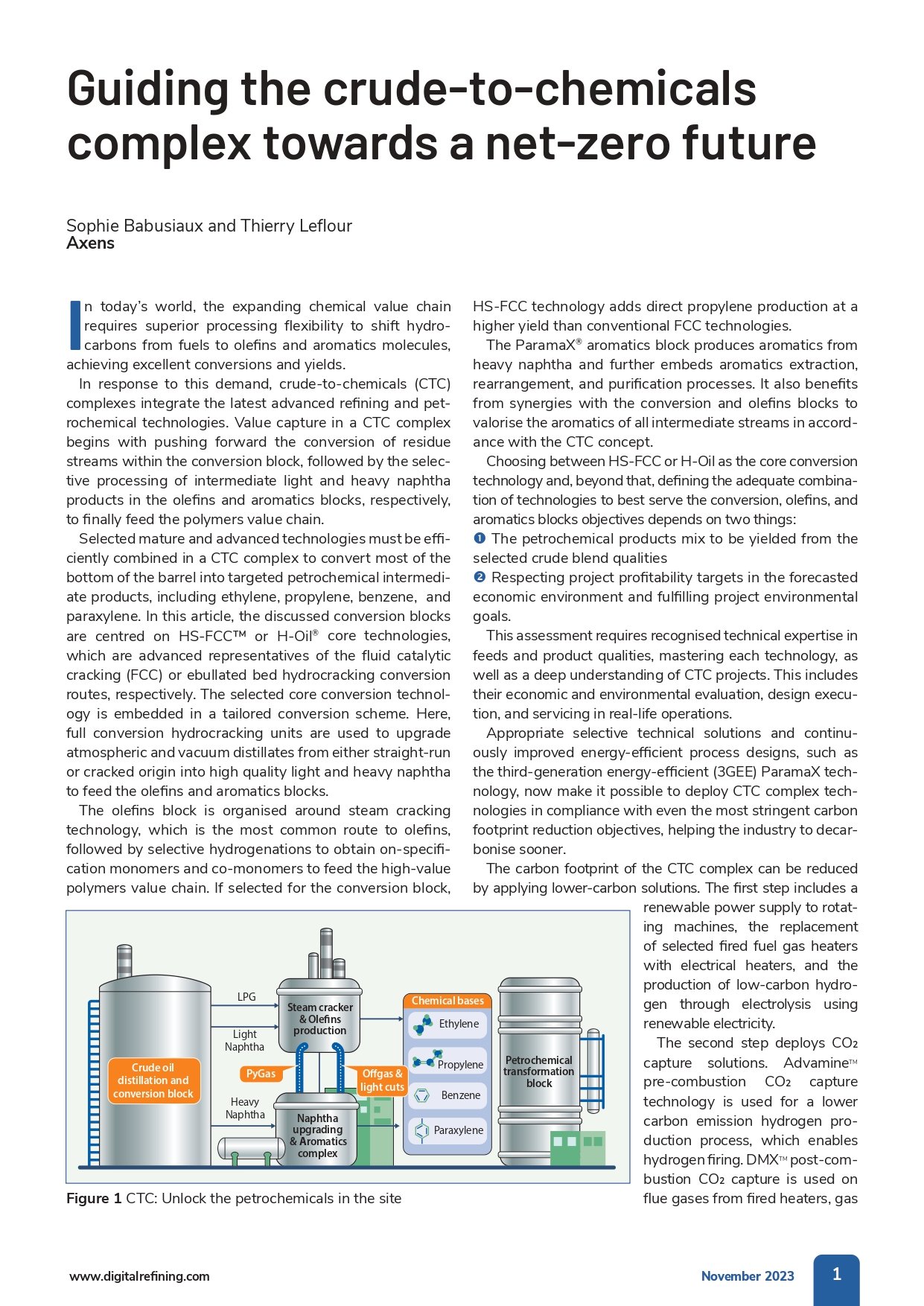

CTC: a straight-forward route for a strategic turn

Valorizing renewable & recycled plastics feedstocks

Axens group provides a complete range of solutions for the conversion of oil and biomass to cleaner fuels, the production and purification of major petrochemical intermediates, the chemical recycling of plastics, all natural gas treatment and conversion options, water treatment as well as carbon capture & storage solutions.

The offer includes technologies, equipment, furnaces, modular units, catalysts, adsorbents and related services.

Axens helps its clients build a sustainable future with inventive and performing solutions.

3,000

Over 3,000 industrial units under license

70,000

Over 70,000 tons of catalysts and adsorbents each year

500

Over 500 modular units references

What we do

From feasibility studies to unit start-up and follow-up throughout the entire unit life cycle, Axens Group is ideally positioned to cover the entire value chain while ensuring the highest level of performance with reduced environmental footprint.

Oil Refining

Petrochemicals & Chemicals

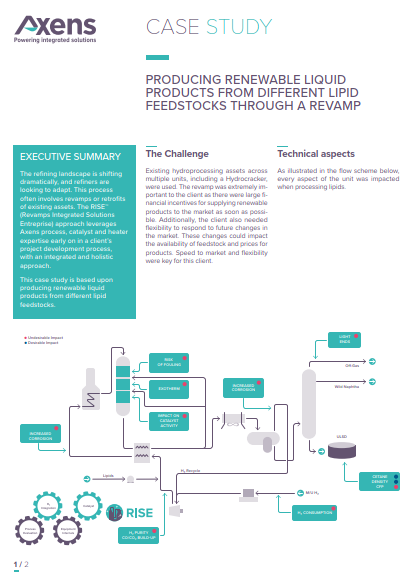

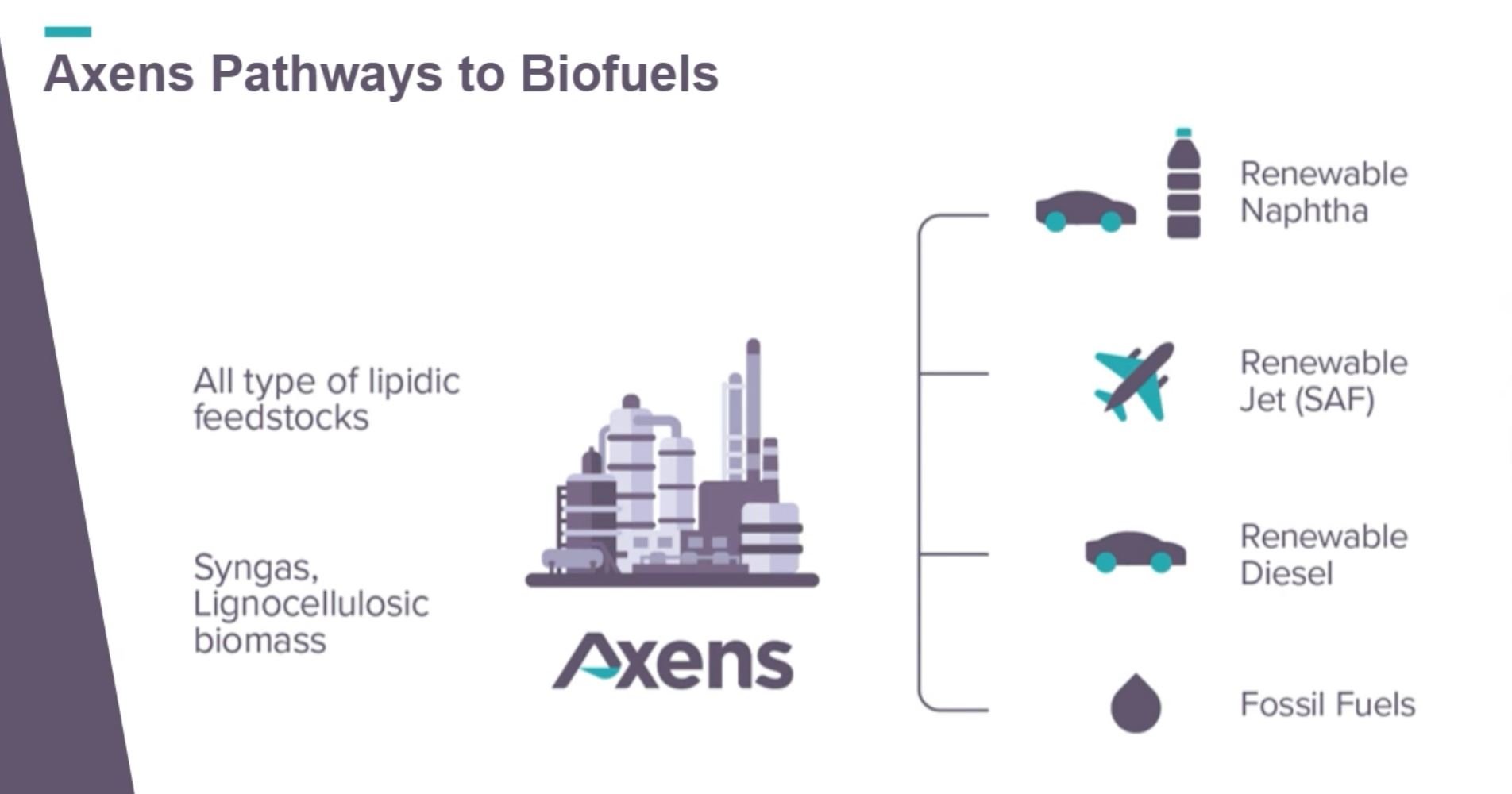

Renewable Fuels & bio-based Chemicals

Water Treatment

Carbon Capture and Storage

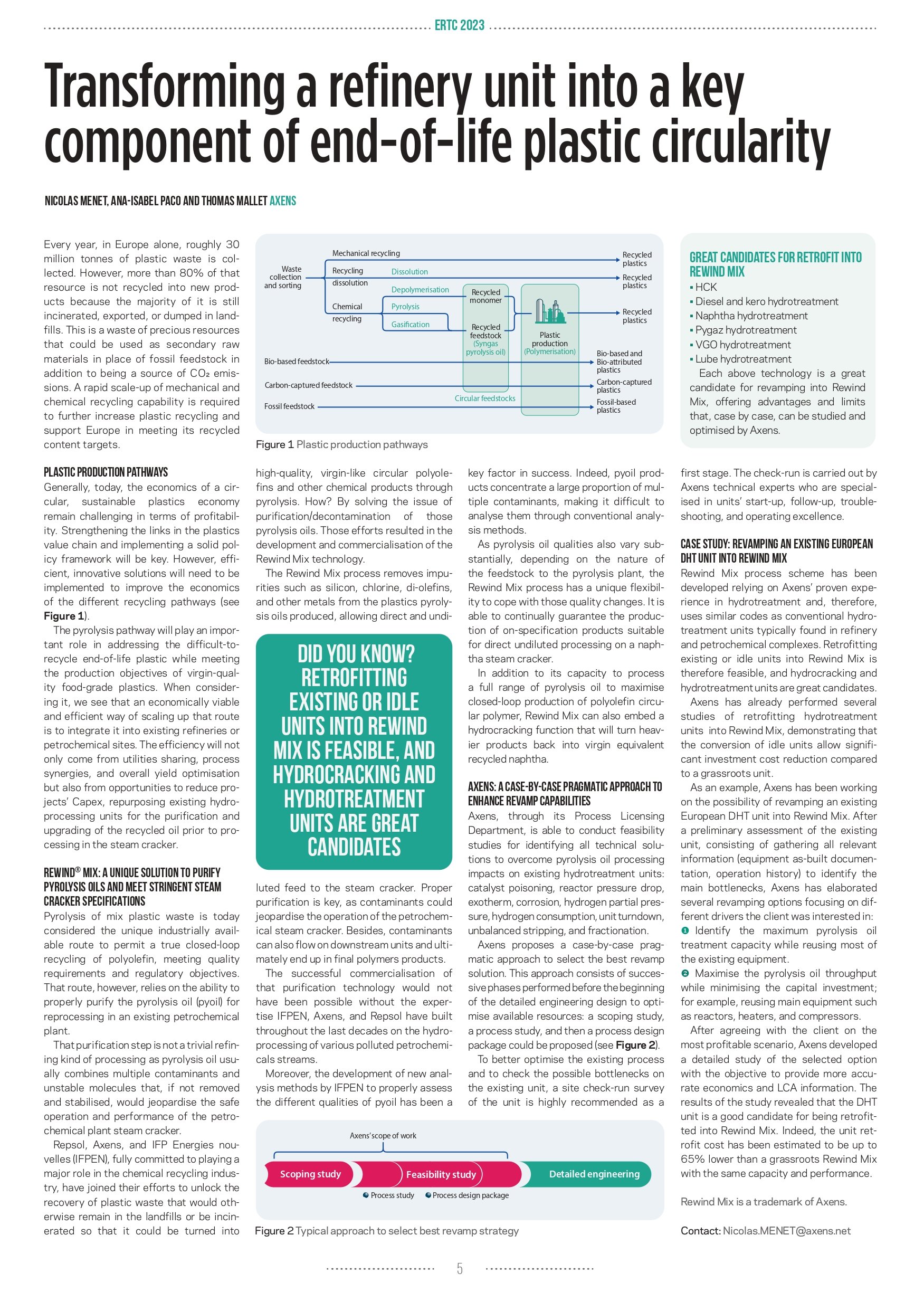

Plastic Recycling

Low Carbon Hydrogen

Upcoming Events

All events

Plastic Recycling

Plastic Recycling

Carbon Capture & Storage

Carbon Capture & Storage